Making of a Hook Tool

As described in the class on Mar 22nd, 2008

|

HOOK TOOLAlan Lacer

|

|

RESOURCES FOR MAKING A BASIC HOOK TOOL:

The hook tool is essentially a right-angle gouge that enables

the woodturner doing inside end-grain hollowing to achieve two

goals: work with the grain and use a cutting rather than a

scraping action.

Although there are a variety of tools on the market in many

shapes-ovals, rings, and tools that look like drill bits-the

hook tool is the predecessor of them all.

Follow the steps below to create a simple hook tool from high

carbon steel. Although high-speed steel has longer edge-holding

properties, the heat-treating procedures are beyond most

woodworking shops. Because you will use this tool primarily as a

finishing tool, the edge-holding properties of this carbon steel

works fine.

KEY TERMS:

Annealed: in a softened state.

Tempering:

the process of bringing hardened steel to a softer,

working hardness for a particular use.

PROCESS:

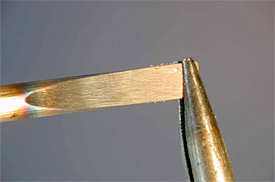

Step 1:

Cut the drill rod with a hacksaw to 9" lengths. Process to

grind one end to the example shown. You can do this with a

wheel grinder, but a belt type grinder is easier and leaves

a better finish. Determine the cutting edge side, but don't

get it sharp at this point. With the cutting edge down, file

the left face to a clean flat face-as this will be the

inside flute of your hook tool.

Grind the blank into this shape. Left: the view from above.

Center: left face (cutting edge down). Right: what will

become the cutting edge.

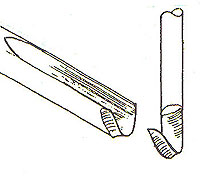

Step 2:

Place the blank in your handle, but don't glue it in just

yet. With your heat source, heat about 1" of the ground end

to a bright cherry red. Using the needle-nose pliers, grab

as near the end as possible and twist to the left to create

the hook (cutting edge pointing downwards). I like to have a

fairly tight flute on hooks for boxes and goblets. Mine look

a lot like a 1/4" to 3/8" bowl gouge flute.

Grip the bright cherry red end of the blank with the needle

nose pliers and bend into a hook--grip near the end to

produce a smaller hook. If the cutting edge is facing

downward, bend the hook to the left.

Step 3:

If you want a little offset of the hook, heat further back

of the hook (about 3/4"), grab the area just below the hook

and bend this time to the right (cutting edge down).

Step 4:

Next it is time to complete the first step of heat treating

and hardening. Heat only the hook to a bright cherry red. Do

this evenly and gradually, and maintain this temperature for

at least a couple of minutes. If you want to use the

Tempilstick, take the 1450 degree one and either pencil it

on the hook area before you start heating or keep touching

the heated hook until it liquefies. After a couple of

minutes of the bright cherry red, quench quickly into the

can of olive oil, stirring rapidly. After about 1 minute,

remove it from the olive oil and test with a mill file: the

hook area should now be harder than your file. Feel the

difference of filing between the unhardened shaft of the

tool and the hook area.

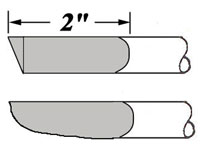

Step 5:

The second step of heat-treating is to temper. If you have

an accurate oven at home, preheat to 490 degrees, then place

the hook tool on a piece of aluminum foil inside of a

shallow pan or cookie sheet. Bake for about 30 minutes,

remove and just allow to air cool. Or, use the oxidation

spectrum to temper by eye: wash using soap and water to

remove all oil off the tool. Sand or wire brush the entire

hook area until it is clean and bright. Heat with your torch

(propane works well for this step as it is cooler than MAPP)

about 2" below the hook. Watch the colors develop and travel

in both directions from the point you are heating. First

will be a spectrum of yellows, then purple, then a spectrum

of blues. Your goal is to allow the dark end of the

yellows-I call it bronze-to reach the hook section.

Go slow-and when colors approach the hook,

remove from heat source and allow conduction to travel the

temperature. When most of the hook is a bronze color, quench

quickly into water to stop the process. You may also use the

500-degree Tempilstick to better judge the temperature.

After hardening the steel, heat well back of the hook and

allow conduction to bring the bronze color up to the hook

area. When it appears an even bronze quench quickly into

water to halt the process.

Step 6:

Sharpen your hook tool. I sharpen these just like a gouge:

ground bevel outside, smooth flute inside. The angle you

grind on the outside will determine whether you can place

the bevel on the wood without hitting the sides of your

project-same issues as with bowl gouges. A good starting

point is about a 15-degree angle facing away from the

hook-cutting edge facing upward. Be careful with your

grinding, as bluing will soften the edge-so quench in water

frequently.

Honing is essential for this tool to get it truly sharp:

hone the outside and finish by honing the inside flute-use a

slip stone for the honing process. Complete the process by

gluing the tool into your handle with slow-set epoxy. Wait

for 24 hours for the epoxy to set before giving it a try.

There you have it. As simple as the process is-and the steel

is quite reasonable-you can afford to experiment with

different versions to fit the types of projects you are

making. Here are several of the key variables: hook shape

and size, degree of offset and the ground bevel angle. For

large projects such as end-grain bowls, go to larger sizes

of drill rod to give greater support.

Experiment with hook shapes, sizes and off-sets. For your

first hook do a simple straight tool with no off-set. Sources:©Copyright 2004 Alan Lacer |

||